UV LED nail lamps usually work in the UVA band, with wavelengths concentrated in the range of 320nm to 410nm, especially the 365nm and 405nm bands are the most common. Ultraviolet rays in this range can activate the photoinitiators in most nail glues, triggering polymerization reactions and transforming nail glue from liquid to solid. The energy density and penetration depth transmitted by different wavelengths directly affect the curing speed, depth and uniformity.

Energy characteristics of different wavelengths

The 365nm band belongs to the shorter UVA, with strong energy and good penetration, and is suitable for deep curing of thicker or high-viscosity nail glue. The 405nm band belongs to the UVA long-wave region, with relatively mild energy, suitable for rapid surface irradiation. Most UV LED nail lamps use a 365+405nm dual-band combination to be compatible with more types of nail glue, thereby improving the overall curing compatibility and efficiency.

Impact on phototherapy gel

Phototherapy gel is the most commonly used type in traditional nail systems, and its curing relies on ultraviolet rays triggering a chain reaction of photoinitiators. Early phototherapy glue was mostly based on the band response between 370nm-400nm, but with the upgrading of technology, more and more manufacturers began to optimize the formula to adapt to the dual-effect UV LED lamps of 365nm and 405nm bands. Therefore, using only 405nm single-band UV LED lamps may cause some traditional phototherapy glues to be incompletely cured, especially at the edge of the nail surface or when the glue layer is thicker.

|

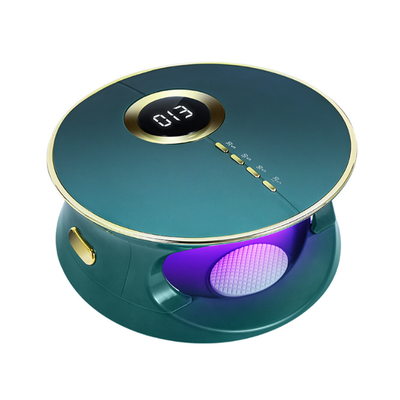

F15 BEADS: 60UV/LED Voltage: 100-240V 50-60HZ Power: 168W Sensor: YES Touch screen keypad: NO Package: 24 PCS/CTN 68*49*47 GW: 15.3KG/CTN |

Impact on nail extension glue

Due to its thicker structure, nail extension glue has high requirements for the penetration and energy concentration of the light source wavelength. The 365nm band has a stronger polymerization driving ability and is more suitable for the deep curing of nail extension glue. Some high-viscosity structural glues such as Builder Gel and Hard Gel are prone to "dry surface and soft bottom" phenomenon under a single band, and must rely on the 365nm band to provide sufficient energy to ensure complete polymerization.

Impact on colored nail polish

Colored nail polish adds pigments, pearlescent, metal particles and other ingredients in the formula, which has a certain shielding effect on ultraviolet rays. Dark or highly saturated colors have a stronger ability to absorb light, making it difficult for UV light to penetrate the bottom layer. The penetration of 405nm band light is relatively weak, and the 365nm band is needed to improve the polymerization efficiency. Some nail polishes such as deep purple, deep red, and royal blue are unevenly cured under a single-band lamp, showing "wrinkling", "not drying" or "fading". Using a dual-band UV LED lamp can effectively avoid such problems.

Impact on cat's eye glue

Cat's eye glue contains magnetic particles, which can form a specific glossy texture with magnets and is highly sensitive to wavelength. The photoinitiator response range used in some cat's eye glue formulas is closer to the 405nm band. If the lamp only uses the 365nm band, the texture will spread and the pattern will disappear before curing. It is recommended to use a lamp with a 405nm main band and a 365nm component to achieve the best curing conditions for texture locking and pattern shaping.

|

|

Impact on low-sensitivity glue

In order to avoid allergic ingredients, low-sensitivity glue often uses new non-traditional photoinitiators, whose response spectra may be concentrated in higher bands such as 405nm or even 420nm. If the wavelength range of UV LED lamps is too low, these initiators may not be effectively activated, resulting in slow curing or incomplete curing. Therefore, low-sensitivity nail glue has higher requirements for the wavelength range of lamps. It is recommended to use multi-band composite UV LED equipment to meet the needs of colloids with different sensitivities.

Impact on transparent sealant

Sealing glue is usually a low-viscosity transparent material, and the curing requirements tend to be fast, surface hardening, and non-sticky. The 405nm band is suitable for the surface curing of the sealant, which can effectively reduce the number of smearing steps and improve the surface gloss. However, if the internal components require higher energy activation, such as adding anti-yellowing factors, mirror molecules, etc., the 365nm band is still needed for support. Single-band equipment may have problems with dry surface but poor scratch resistance when processing high-end sealants.

English

English Español

Español