How does the number of lamp beads of UV LED nail lamp affect the curing effect

The impact of light coverage

The core function of UV LED nail lamp is to make the photosensitizer in the nail glue polymerize through ultraviolet irradiation of a specific wavelength, thereby achieving rapid curing. The number of lamp beads determines the distribution density of the light source inside the lamp cavity. The more lamp beads there are, the wider the irradiation range can fully cover every finger and even toe, significantly reducing the blind spots of light. When using products with a small number of lamp beads, users need to constantly adjust the position of their fingers to ensure that each nail is irradiated, which can easily lead to uneven curing and partial undrying. The high lamp bead density design can achieve simultaneous curing of five fingers, improve operating efficiency, and enhance the overall user experience.

Increase in curing speed

The number of lamp beads directly affects the total radiation power. Under the same wavelength and LED quality, the more lamp beads there are, the greater the light energy released per unit time, and the energy threshold required for nail glue can be reached faster, thereby accelerating the curing process. The high-efficiency UV LED lamp bead array can complete the hardening of ordinary nail polish in 30 seconds, compared with more than 60 seconds for low-lamp bead equipment, and the work efficiency is significantly improved. Especially in commercial nail salons, fast turnover is of great significance to customer satisfaction and service efficiency.

Light uniformity and curing consistency

Uniform lighting is the key to high-quality curing. A large number of lamp beads and reasonable distribution can ensure uniform light in the irradiation area to avoid local overexposure or insufficient light. If there are too few lamp beads or they are arranged in a concentrated manner, it is easy to form a phenomenon of "strong center and weak edge", resulting in some nails being completely cured and some still in a semi-solid state, affecting the durability and visual effect of nail art. Especially when using nail glue with complex structure or darker color, uniform lighting is more important.

Thermal experience and safety optimization

A high number of lamp beads does not necessarily mean a higher thermal sensation. By scientifically arranging the lamp beads, heat can be dispersed to avoid local overheating causing burning sensation on the user's fingers. Some high-quality products are designed with intelligent temperature control chips and zoned lighting technology to achieve progressive heating and reduce the "thermal shock" phenomenon. Low-end lamp beads are few and the concentrated area heats up violently, which can easily cause discomfort or even minor burns. Reasonable increase in the number of lamp beads can help to release heat evenly and improve overall comfort and safety.

Enhanced multi-band coverage

Modern UV LED lamp beads often use a dual-band combination of 365nm and 405nm to adapt to different brands and types of nail glue. Increasing the number of lamp beads can make lamp beads of different bands staggered and enhance the uniformity of wavelength coverage. For some special materials such as Builder Gel, Poly Gel, etc., precise irradiation of specific wavelengths is required. The more lamp beads there are, the more balanced the mixing of energy in different bands can be achieved, thereby achieving better curing effect. Low lamp bead equipment often causes some nail glue to fail to fully cure due to incomplete bands, and even causes problems such as surface drying and bottom softening.

Improved equipment stability and redundancy

LED lamp beads have light decay and aging during long-term use. Equipment with a large number of lamp beads can still maintain normal use when facing partial lamp bead loss, which will not affect the overall curing effect, and has good stability and redundant fault tolerance. Once a small number of lamp bead equipment is partially damaged, the energy output will be greatly reduced, resulting in incomplete curing, affecting the service life and user trust. High-lamp bead equipment can extend the maintenance cycle and reduce the after-sales failure rate.

Balance between power consumption management and heat dissipation design

Increasing the number of lamp beads within the power control range requires matching a better heat dissipation system and power management module. High-end products usually use aluminum substrate heat dissipation and forced air cooling design to ensure that the lamp beads work within a safe temperature range and maintain efficient luminous performance. Reasonable increase in lamp beads will not significantly increase energy consumption, but can effectively improve luminous efficiency. While optimizing the layout of lamp beads, it reduces the risk of heat concentration and makes the whole machine run more stably.

|

|

What is the wavelength range of UV LED nail lamps?

UV LED nail lamps emit ultraviolet rays of a specific wavelength to activate photosensitive components and cause the photoinitiator in the nail glue to polymerize, thereby achieving rapid curing. Ultraviolet rays (UV) are divided into UVA (315–400nm), UVB (280–315nm) and UVC (100–280nm) according to their wavelengths. Among them, the nail lamp uses the UVA band, which has moderate light energy and will not cause direct burns to the skin. At the same time, it has enough energy to activate the photoinitiator in the nail glue and complete the polymerization curing process.

Common wavelength range: 365nm and 405nm dual band

Most mainstream UV LED nail lamps in the market adopt a dual-band design of 365nm and 405nm to form a broadband coverage, which effectively improves the compatibility and curing effect of different nail glue materials.

The 365nm wavelength belongs to the pure ultraviolet band and has high energy. It is the activation wavelength required by many traditional phototherapy glues. It can penetrate deeply into the bottom layer of nail glue, effectively promote deep curing, and prevent the surface from drying and softening. This band is suitable for high-viscosity materials such as structural glue (Builder Gel), extension glue (Hard Gel), and some transparent sealing layers.

The 405nm wavelength is between ultraviolet and visible light, and its penetration is relatively weak, but it has the advantage of gentle irradiation. This band is widely used in modern phototherapy nail polish, color glue, cat's eye glue and other surface products. Its characteristics are fast, uniform, gentle and non-scorching, reducing irritation to nails and skin.

Advantages of dual-band combination

The dual-band design has the dual advantages of deep curing and surface irradiation. 365nm provides strong penetration to ensure that the bottom glue layer is fully polymerized, while 405nm accelerates the photochemical reaction of the surface and improves the overall curing speed. The combined effect of dual wavelengths can effectively prevent problems such as warping, cracks, bubbles, etc. caused by uneven curing, and significantly improve the durability and texture of the finished nail art.

Single-band nail art lamps have obvious limitations. For example, only 365nm band equipment will have problems such as slow drying and strong heating when curing color glue; while only 405nm equipment will be difficult to cure in place when using thick glue or extended glue, and it is easy to produce hidden dangers such as false hardness or softening. The dual-band system is fully compatible with all types of nail glue, from soft glue, color glue to construction glue, covering all scenarios and improving practicality.

Technical realization of multi-band LED lamp beads

Modern UV LED nail lamps integrate lamp beads of different wavelengths and arrange them in combination to form a complete wavelength coverage system. The common design is that 365nm and 405nm lamp beads are arranged in a certain proportion to effectively avoid blind spots. Some high-end products also introduce the 395nm intermediate band to achieve three-band mixed output and further optimize the curing efficiency.

In terms of lamp bead configuration, the common ratio is 365nm: 405nm = 1:2 or 1:1, depending on the product positioning and usage scenario. Professional equipment tends to be equipped with more 365nm lamp beads to meet the curing needs of structural glue and high-viscosity nail glue. Home portable products focus more on the 405nm band to ensure a gentle and non-irritating irradiation experience.

Wavelength stability and light decay control

The stability of the wavelength has a direct impact on the curing effect. High-quality UV LED lamp beads can keep the output wavelength from drifting during long-term operation, ensuring consistent curing effects every time they are used. After frequent use, inferior lamp beads are prone to wavelength shift, which causes some nail glues to fail to activate and cure, affecting the quality of nail art.

Light decay is an important indicator of UV LED lamp bead aging. High-quality LED products use chip-level temperature control technology and high thermal conductivity material packaging to effectively control the light decay rate and maintain long-term stable output. Usually, the life of UV LED lamp beads of regular brands can reach more than 30,000 hours, and the wavelength stable output range is within ±5nm, ensuring the quality consistency of manicurists during long-term use.

What are the advantages of UV LED nail lamps compared with traditional UV lamps?

Differences in light source types

UV LED nail lamps use solid-state light-emitting diodes as ultraviolet light sources, and emit UV light of specific wavelengths through semiconductor chips. Traditional UV lamps use fluorescent ultraviolet lamp tubes, which are filled with mercury vapor and generate ultraviolet rays through discharge. There are fundamental differences between the two in terms of light-emitting principles, structural composition and energy efficiency performance, which directly determine their performance differences in nail art curing applications.

Higher wavelength accuracy

UV LED lamps usually adopt a dual-band design of 365nm and 405nm, with fixed and stable wavelengths, which are suitable for a variety of modern nail glue formulas. The wavelength range of traditional UV lamps is wide, concentrated between 320nm-400nm, and the wavelength distribution is not concentrated, and the efficiency of activating photosensitizers is low. UV LED technology achieves precise control of wavelengths, improves curing reaction efficiency, reduces irradiation time, and improves curing depth and uniformity.

Significantly improved curing speed

UV LED nail lamps can complete most nail glue curing tasks within 10 to 60 seconds. Traditional UV lamps usually take 120 seconds or even longer to complete the same curing process. Because UV LED output light energy is more concentrated and energy conversion efficiency is higher, it can quickly reach the polymerization energy threshold required for nail glue, significantly improving the efficiency of nail art operations, especially suitable for commercial high-frequency scenarios.

Longer service life

UV LED lamp beads generally have a service life of 30,000 to 50,000 hours, and are not prone to lamp bead burnout or severe light decay. The service life of traditional UV lamps is generally only 3000 to 5000 hours. As the use time increases, the ultraviolet output will decay and need to be replaced regularly. UV LED products can still maintain high-intensity output after long-term use, reducing maintenance costs and improving equipment reliability.

Lower energy consumption and more energy-saving

UV LED lamps have excellent energy efficiency ratio and can achieve higher intensity ultraviolet output at the same power. The light conversion efficiency of traditional UV lamps is low, and a large amount of electrical energy is lost in the form of heat energy, resulting in energy waste. UV LED does not need to be preheated, it lights up as soon as it is powered on, has low power consumption, is energy-saving and environmentally friendly, and conforms to the modern green consumption concept.

Environmentally friendly mercury-free design

UV LED adopts mercury-free light source design, does not contain harmful heavy metals, and is safer for the human body and the environment. Traditional UV lamps contain trace mercury elements, which will release toxic substances once broken, posing health and environmental risks. In the nail industry environment, UV LED equipment is more in line with safe operation standards and is suitable for long-term intensive use.

Fast startup speed

UV LED nail lamps have the characteristics of turning on and lighting up immediately, without preheating time, and can achieve full light output instantly when powered on. Traditional UV lamps usually require a preheating process of several seconds to tens of seconds when starting, which affects the work rhythm. Especially in high-frequency switching environments, LED equipment has more operational flexibility and response speed.

More compact size and lighter structure

The UV LED light source is small in size and has high heat dissipation efficiency. It can be integrated into a lightweight body to achieve a portable design. Traditional UV lamps are bulky, heavy, and inconvenient to move because they need to carry lamp tubes, reflectors, and rectifiers. Modern UV LED nail lamps are designed to be wireless, portable, and multifunctional, suitable for use in multiple scenarios such as home, outings, and salons.

Higher heat dissipation efficiency

The operating temperature of UV LED equipment is relatively low. The heat can be quickly dissipated through an aluminum substrate or air cooling system to reduce the surface temperature of the body and avoid burning hands. Traditional UV lamps heat up quickly during operation, and heat accumulates inside the cavity, which can easily cause burning or discomfort, affecting user experience.

Higher safety

The UV LED output spectrum is concentrated, with almost no infrared and blue light radiation, and is significantly less irritating to the skin and eyes than traditional UV lamps. Modern UV LED nail lamps are often equipped with multiple safety features such as intelligent sensing, over-temperature protection, and low-temperature mode to improve safety. Traditional UV lamps have a wide spectrum, contain blue light and heat radiation, and long-term use can easily cause aging and discomfort to the hand skin.

|

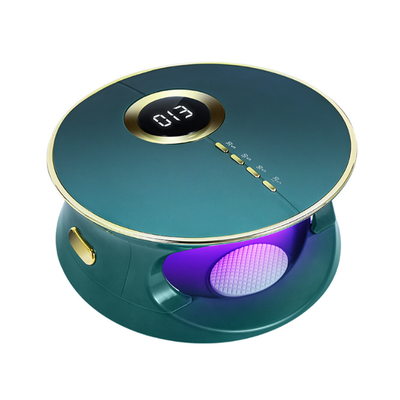

BQ-V15 BEADS: 30(365nm+405nm)uv/LED+6(660NM) Voltage: 110-240V 50-60HZ Power: 128W Sensor: YES Touch screen keypad: YES Package: 20PCS/CTN 55*51*58 CM GW: 19KG/CTN 1. Red light beauty 2. Desk lamp 360 glue baking 3. USB port can be used for polishing pens and phone charging |

Is the installation and maintenance of UV LED nail lamp convenient?

The structural design is highly integrated

The UV LED nail lamp adopts a modular integrated design, integrating the lamp beads, power supply, heat dissipation system and shell in a compact structure. There are no complex mechanical parts inside, no external ballast or transformer is required, and it can be used after power on. Compared with traditional UV lamps, it eliminates the tedious processes such as lamp tube installation, reflector adjustment, and lamp holder replacement, which significantly reduces the difficulty of installation.

Plug-in and play design

Most UV LED nail lamps are plug-and-play structures, which only need to be connected to the power adapter or USB interface, and no tools are required for assembly. Some portable models are equipped with built-in lithium batteries and charged through Type-C or Micro-USB ports to meet the needs of mobile use. For professional salon users or home users, the equipment can be enabled without professional technical background, and the operation is highly user-friendly.

Automatic sensing system reduces the operating burden

Modern UV LED nail lamps are widely equipped with intelligent infrared sensing systems. When the user puts his hand into the lamp cavity, the irradiation is automatically started, and it is automatically turned off after removing it. This type of system uses a photoelectric switch and a sensing chip integrated module, which not only reduces button wear, but also avoids human operation errors. No need to touch the equipment frequently, effectively improving hygiene safety and ease of use.

Internal lamp bead replacement-free design

The life of UV LED lamp beads is as long as 30,000 to 50,000 hours, which is much longer than the service life of traditional UV lamps. Most UV LED nail lamps are sealed structures, and the internal lamp beads are fixed on the aluminum substrate or PCB board. Users do not need to replace the lamp beads or adjust the position. Maintenance-free throughout the life cycle, reducing the frequency of replacement of consumables and maintenance costs. Compared with the frequency of replacing lamps every 3-6 months for traditional UV lamps, UV LED equipment has more advantages in long-term use.

Optimized arrangement of lamp beads to reduce failure rate

The lamp beads are mostly arranged in parallel or array. Even if some LED units are light decaying or failing, the remaining lamp beads can still operate normally without affecting the overall irradiation effect. This fault-tolerant design ensures that the equipment can still work stably under long-term high-frequency use. Most products use SMD patch technology or COB packaging technology to improve the reliability of electrical connections and reduce maintenance requirements.

Shell material is wear-resistant and pressure-resistant

The shell is mostly made of ABS high-strength plastic or PC flame-retardant material, which has good anti-fall, heat resistance and corrosion resistance, and is suitable for the frequent operation environment of the salon. Some high-end models add aluminum alloy frames, silicone anti-skid pads and dustproof grilles to the shell design to improve the protection level of the whole machine and extend its service life. The structure is stable and no special protection measures are required during transportation and installation. It is suitable for e-commerce sales and remote delivery.

Removable bottom plate design for easy cleaning

Most UV LED nail lamps are equipped with removable bottom plates, which can be quickly loaded and unloaded through magnetic suction or snap-on structures. The bottom plate is convenient for daily cleaning of nail glue residues to avoid dirt accumulation and affect sanitary conditions. The open bottom design is suitable for different operation scenarios of hands and feet. Users can freely adjust according to their needs to improve flexibility. No tools are required during cleaning, and basic maintenance can be completed by wiping with a wet cloth or alcohol.

Improved circuit safety and reduced fault frequency

The products generally have built-in safety modules such as overvoltage protection, overheating protection, and short-circuit protection to ensure that the circuit system automatically cuts off or limits current under abnormal conditions to prevent damage to internal components. During use, in the event of voltage fluctuations, frequent switching, etc., the UV LED lamp can still maintain stable output and reduce the probability of electrical failure. Most power adapters comply with international certification standards such as CE, FCC, and RoHS to ensure user operation safety.

The display and control interface is simple and intuitive

The control panel design tends to be simplified. Common configurations include 30-second, 60-second, 90-second timer buttons. Some high-end models provide LED digital displays or touch-sensitive panels. The panel is waterproof and dustproof, and the buttons are responsive. Users can quickly get started without consulting complex manuals. Some models support intelligent memory function, and the last setting is automatically saved to improve operating efficiency.

The routine maintenance process is simple and clear

In daily use, the UV LED nail lamp only needs to clean the shell and check the power interface regularly. It is recommended to clean the dust and nail powder on the inner wall of the lamp cavity every week to keep it transparent and clean; check whether the adapter connector and the power cord are firmly plugged in and out every month; check whether the switch button or the sensing system is sensitive every six months. All maintenance links can be completed independently by the user without relying on after-sales technical support.

Why Choose Us |

|

|

|

|

|

|

| We guarantee to output high-quality products to you. | A laboratory with advanced testing equipment. | We have a good cost control system. | We have a professional team of designers. | We have rich experience in collaborating with foreign brands. | A professional sales team is at your service. |

English

English Español

Español